|

|||||||||||||||

| |

New

Generation Slip Resistant Metal Flooring |

|

|||||||||||||

|

|||||||||||||||

|

|||||||||||||||

|

Durability The durability of New Generation Slip Resistant Metal Flooring originates with the substrate selected. It is available in Carbon Steel, Stainless Steel, Aluminum and other alloy metals, in 14 gauge ASTM-A-569 steel, to any thickness of ASTM A-36 steel for structural applications, or in the alloy and thickness that you require. New Generation Slip Resistant Metal Flooring provides the best slip-resistant surface available. While these durable steel substrates provide a solid foundation for the finished product, substrate strength is only the beginning. The true life-cycle of safety floor plates is traditionally determined not by the substrate, but rather slip-resistant properties generated by the traction surface. The traction providing laser depositions on New Generation Slip Resistant Metal Flooring have been tested for hardness and adherence by independent testing laboratories and these results assure that this generation of flooring will provide unsurpassed service life. Laboratory analysis has measured the hardness of New Generation Slip Resistant Metal Flooring traction providing custom alloy laser depositions at up to 60 on the Rockwell C Scale. Under the heaviest pedestrian or vehicular traffic, these deposits will provide continuous, safe, effective service. (Be reminded, that similar to all abrasive surface steel safety floor plates, New Generation Slip Resistant Metal Flooring should not be installed in areas subject to steel-wheeled vehicular traffic.) The cross-sectional photograph below illustrates the deep penetration of the symmetrical laser deposition into the steel substrate. Laboratory tested, the deposition penetrates the steel substrate and is enclosed by a strengthened heat affected zone. The resulting bond strength combined with the proven deposition hardness provides unsurpassed durability regardless of wear or abrasion.

|

|||||||||||||||

|

|

|||||||||||||||

| Cross sectional view. |

|||||||||||||||

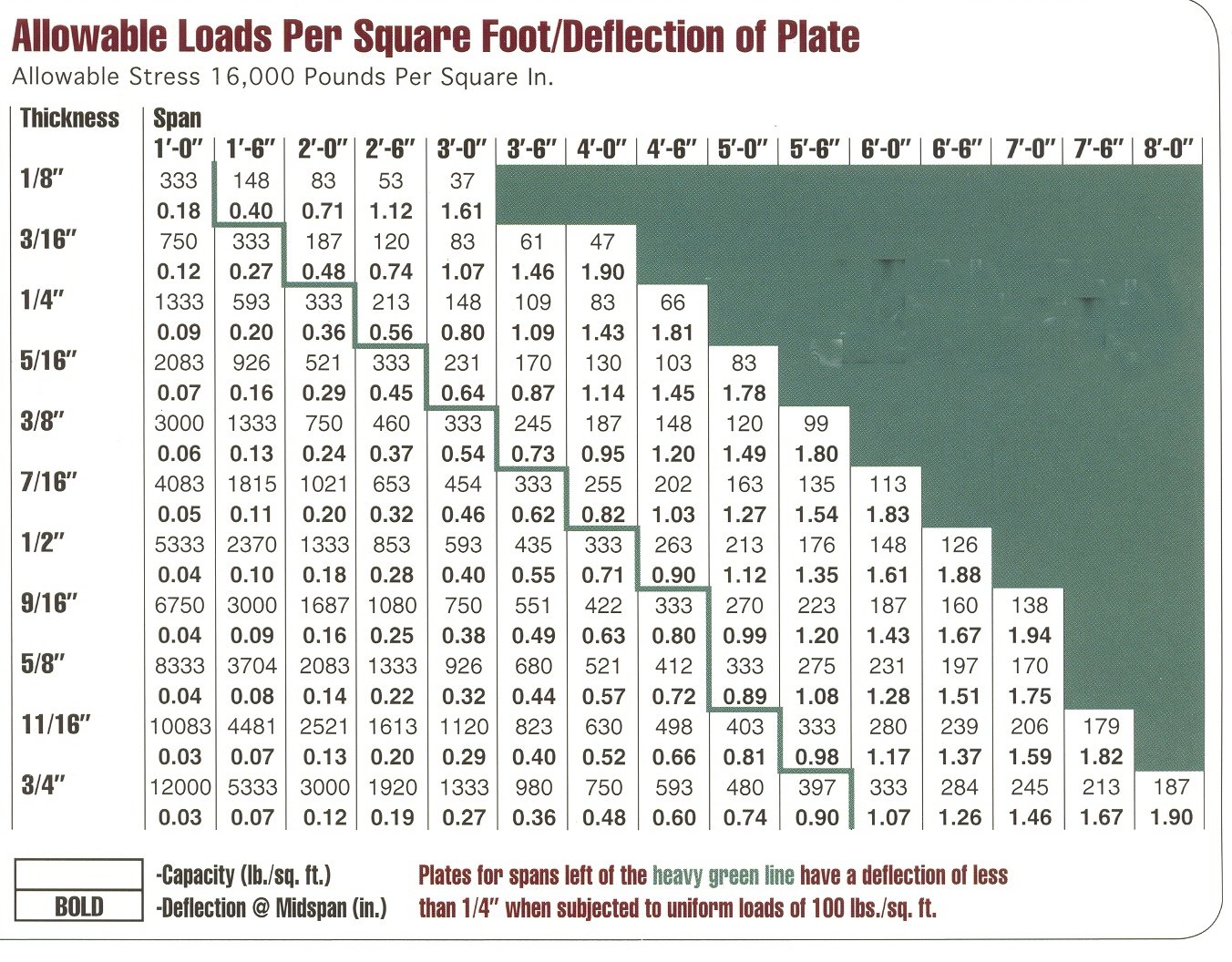

| Load Table - Click on Load Table Chart to read full sized. |

|||||||||||||||

|

|

|||||||||||||||