|

|||||||||||||||||||||||||||||||||||||

| |

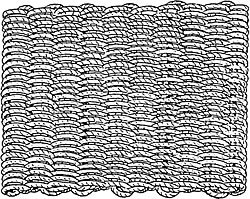

Braided

Manila Industrial Rope Floor Mats |

|

|||||||||||||||||||||||||||||||||||

Braided Manila Industrial Rope Mats and Related Products are used for a variety of applications. In the automotive industry, they are used to protect metal molding dies during maintenance and die changing procedures. In the mining industry, they are used as blast mats to contain debris generated by controlled blasting. During the installation or servicing of heavy motors, when the motor parts would be exposed to potential damage if allowed to rest on hard cement floors, Braided Manila Industrial Rope Mats are used as a soft yet durable interface to provide the sensitive parts of the motors with the protection they need. The mats also allow oils to leak out but drain through without causing problems to the machinery or to workers. Braided Manila Industrial Rope Mats are usually equipped with lifting straps in the corners for easy access with fork lifts or by hand. The straps are made of webbing capable of holding up to 10,000 lbs. Pounds are typical of breaking strength/tensile and increases as the diameter of rope increases. The mats can be equipped with metal rings or a variety of other metal devices, such as shackles, hooks or other hardware, if needed. It is important that we be informed as to the type of hardware needed, the number of pieces of each type required and the location of each unit. A measured drawing detailing everything about the mat to be made will help in the preparation of a complete proposal for the requester's consideration. The mats are shipped on skids and can be produced in a week or two depending on sizes and quantities required. Braided Manila Industrial Rope Mats can and often are used as bumpers but such bumbers can also be fabricated using 3-strand nylon rope if requested. When making a bumber it is important to know the preference as to thickness of net, which is to say we need to know the distance between dock fender and wharf, which can range anywhere from 1/2" up to 2", which would, then, guide us in selecting of the right rope to use in making the finished product. |

|||||||||||||||||||||||||||||||||||||

| |

|||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||