|

|||||||||||||||||||

| |

Top

Echelon Elevator Protective Wall Pads - How to Order |

|

|||||||||||||||||

|

How

to Order Top Echelon Protective Wall

Pads

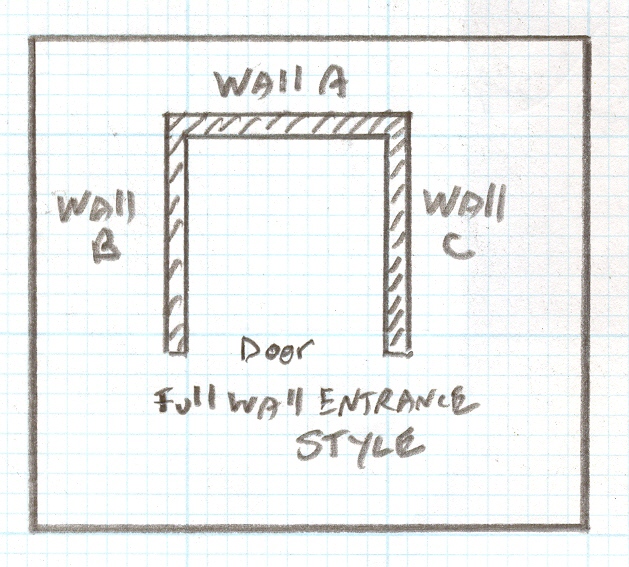

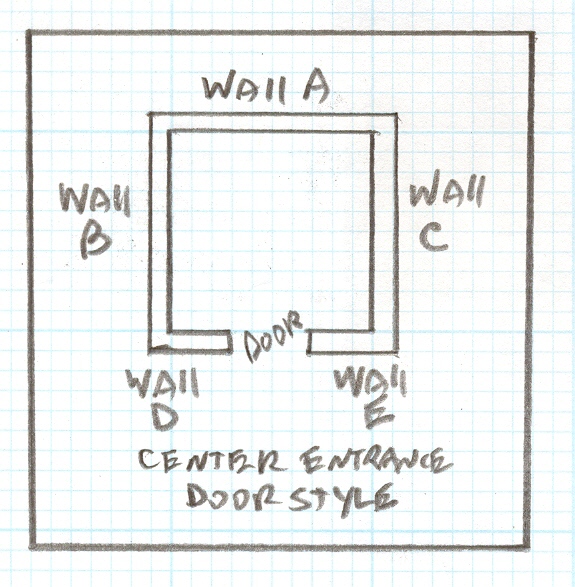

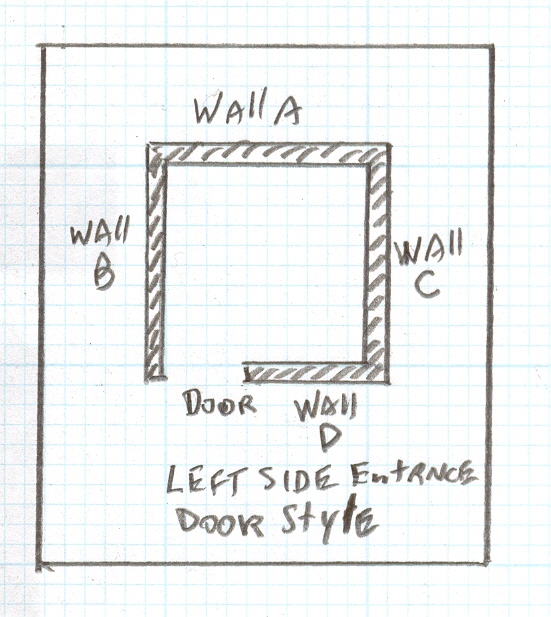

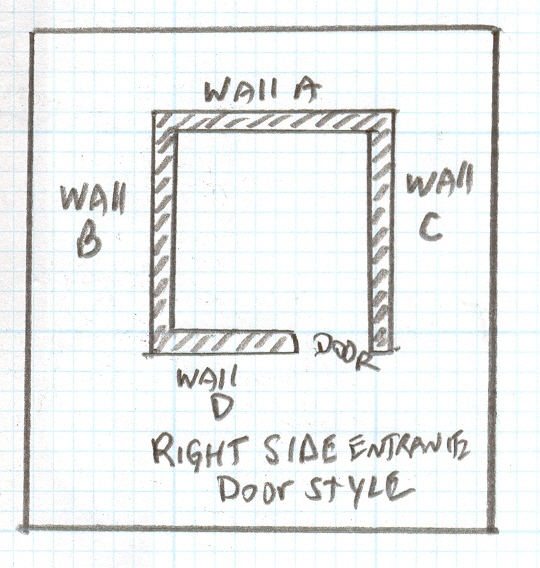

Top Echelon Elevator Protective Wall Pads can be fabricated to conform to any existing elevator cab configuration and can be provided with several different types of hardware for attaching the pads to the walls. Please provide the following information along with the destination city, state, and Zip Code, with contact phone numbers, for a custom quotation. Production or turnaround time is normally two to three working days. Rush orders can be shipped within one to two days and overnight delivery service is available. Custom Quotations: Prices for Top Echelon Elevator Protective Wall Pads are custom quoted on a "job-by-job" basis. Please provide the information described below along with company name, contact person, phone and fax numbers, e-mail address, destination city, state and Zip Code and the number of elevator cabs requiring pads. Thank You. Step 1. Elevator Cab Style

Step 2. Select Pad Style

|

|||||||||||||||||||

| Step 3. Select Pad Material and Pad Color - See Color Chart |

|||||||||||||||||||

|

Step 4. Height of Pads: Provide the dimensions of pads needed. The bottom of the pads should be 4" above the floor of the cab to comply with fire codes. Grommets will be located 1" from top of pads unless otherwise specified. Step 5. Special Additions:

Step 6. Hardware: See Removable Hooks, Permanent Hooks and Studs. Step 7. Pad Widths and Grommet Locations: Provide the following information for each elevator pad labeling ach Elevator Cab and each Wall per Cab Style. Grommets are available in two sizes; #5 Grommet, which is 5/8" inner diameter and #6 Grommet, which is 3/4" innner diameter. The #5 Grommet is provided unless otherwise ordered.

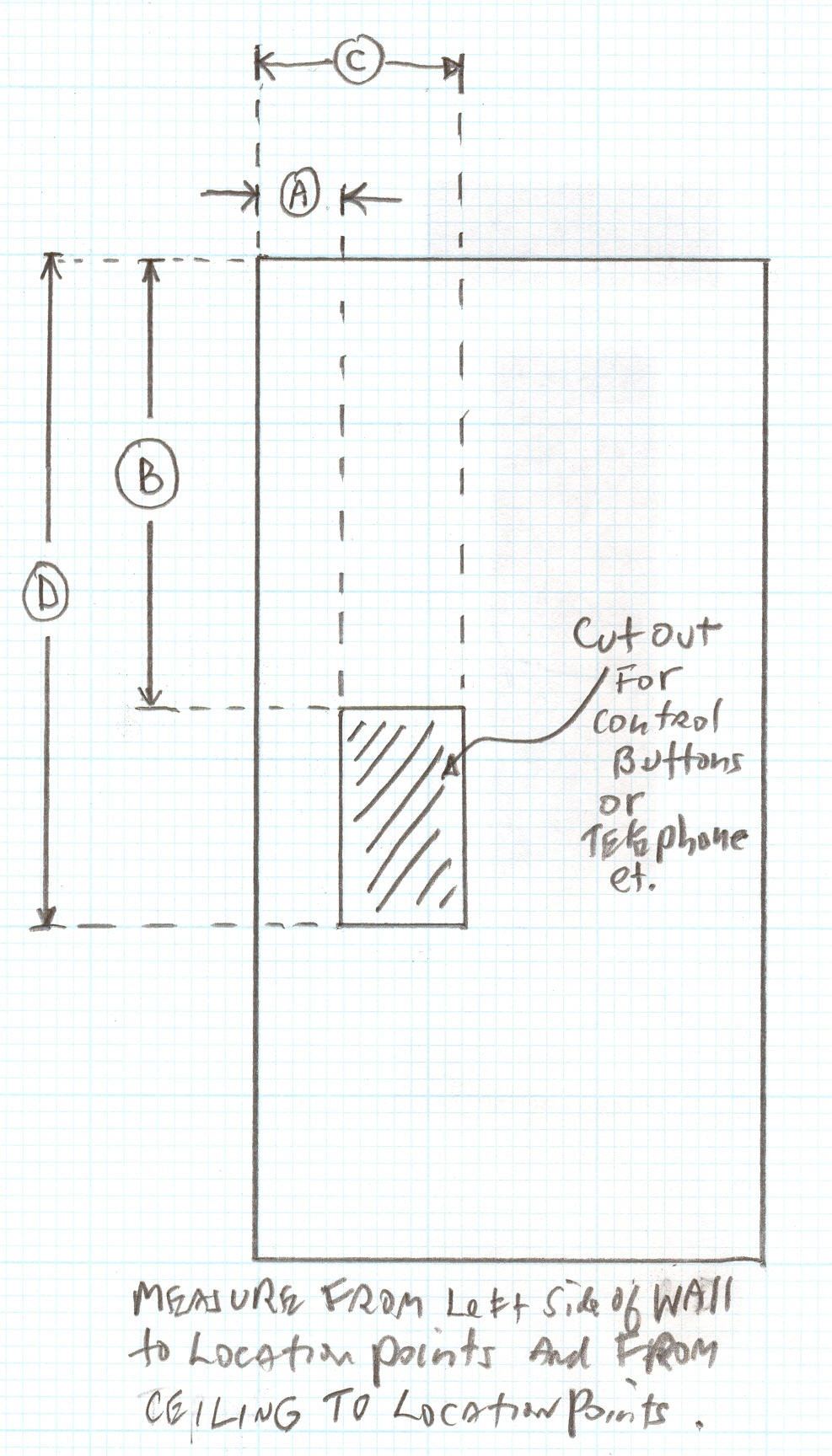

Step 8. Cutouts: Indicate desired Cutouts for each panel requiring one according to thfollowing diagram:

Special Requirements: Top Echelon Elevator Protective Wall Pads are made to order. Special requirements involving additional sewn-in modifications can usually be accommodated and will be quoted on request. An example of such special needs is the inclusion of Rear Pockets on elevator pads. Rear Pockets are virtually an entire second layer of padding sewn securely to the sides and bottom edges of each elevator pad allowing for the insertion of wood panels or other similar material to afford an even higher degree of protection for elevator cab walls. Another example: Most often the ceilings of elevators are left unprotected even though there are situations where light fixtures and ceiling finishes may be subject to being damaged when the cab is used for unusually shaped items. Architects, Designers or Building Facility Managers are invited to request custom solutions by identifying the available means of support for ceiling pads such as may be located in the corners, at the top of the walls or on the ceiling itself, along with drawings locating the sizes and shapes of the ceiling lighting fixtures for each elevator car. For Custom Quotation: Please provide the above information along with company name, contact person, phone and fax numbers, e-mail address, destination city, state and Zip Code, the number of elevator cabs requiring pads. Thank You. |

|||||||||||||||||||

|

|||||||||||||||||||

|

|

|||||||||||||||||||