Flight

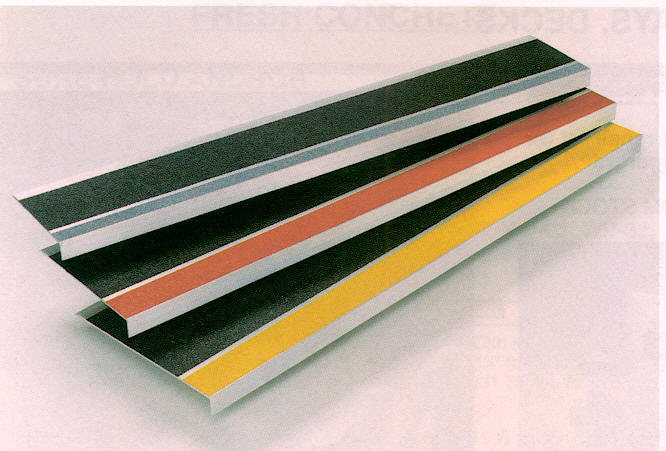

Fixer Safety Renovation Stair Treads Features

|

|

- Longwearing,

newly designed, heat treated, extruded aluminum base.

|

- Available

in many contrasting colors.

|

- Tread

surface covered with Traction Tape safety surface.

|

- Easily

installed to give quick anti-slip protection.

|

- Specify

rubber based construction adhesive for installation.

|

- Standard

tread design without drilled and countersunk holes. Addition

of holes must be specified (consult The Mat King).

|

Architectural Speifications

Maintenance

Instructions

Installation Guidelines

|

The use of Stair Leveling Compound to fill worn steps before

installing Stair Repair Aluminum & Abrasive Grit Tread System

treads is important. To

insure best results, specify Rubber Based Construction Adhesive

in addition to mechanical fasteners for installation.

NOTE: When installing finished wood, specify that the

Stair Repair Aluminum & Abrasive Grit Tread System surface

be factory sealed. |

| |

| Flight Fixer Safety Renovation

Treads |

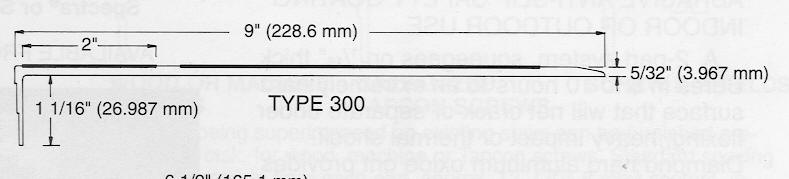

| Product

Number 9832-100-0311 |

|

| |

| Flight Fixer Safety Renovation

Treads |

| Product

Number 9832-100-0300 |

|

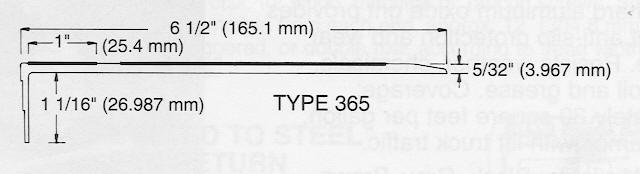

| |

| Flight Fixer Safety Renovation

Treads |

| Product

Number 9832-100-0365 |

|

| |

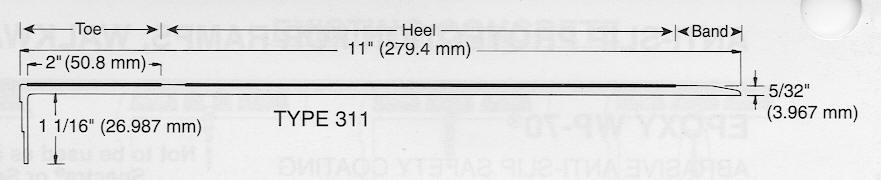

Flight Fixer Safety Renovation

Treads General Specifications |

Flight Fixer Safety Renovation

Treads are manufactured for The Mat King, which is a d/b/a of

Geoffrey Drew Marketing, Inc. The tread base is made of Alloy 6063-T5 extruded

aluminum, with a 5/32" thickness minimum. The anti-slip

surface is chemically bonded onto the extrusion with an adhesive

matrix that is capable of 7.3 Ibs. per sq. in. peel strength

- PSTC-1. The anti-skid surface is level with all surfaces of

the extrusion. Treads are non-combustible as tested under Federal

Test Method Standard No.501 a, Method 6411, Mil-D-STD-1623D,

Treads meet Mil-D-17951 E, Motor Vehicle Safety Standard No.302

Treads are U.S.D.A. approved. Treads have a coefficient of Friction

per specification Mil-D-17951 E that is equal to or greater

than 1.24 Dry and 1.02 Wet. |

| |

Flight

Fixer Safety Renovation Treads

anti-skid surface consists of a uniform "closed coat"

of the specified grade of mineral abrasive. The abrasive is

adhered to the substrate with a flexible polymeric binder, in

sufficient thickness to achieve both optimum bond and grit exposure. |