| |

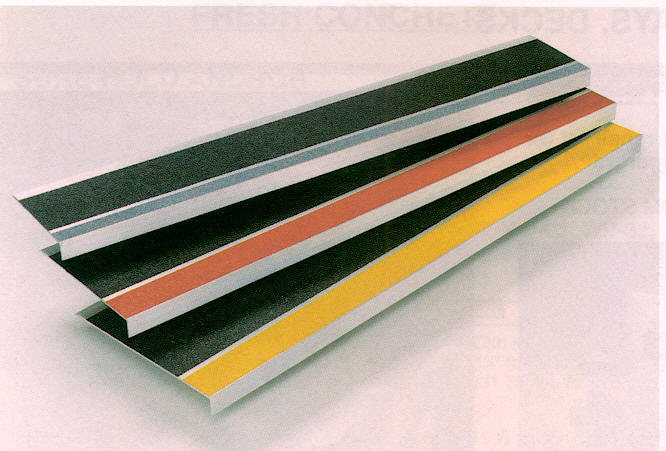

FLIGHT FIXER SAFETY

RENOVATION STAIR TREADS SPECIFICATION

Provide Flight

Fixer Safety Renovation Stair Treads type

safety nosings (select appropriate size):

- 11 inches wide

Product Number 9832-100-0311 (Type 311)

- 9 inches wide Product

Number 9832-100-0300 (Type 300)

- 6-1/2 inches wide

Product Number 9832-100-0365 (Type 365)

as provided by The

Mat King a d/b/a of Geoffrey Drew Marketing, Inc.

for interior and exterior stairs.

- Tread base shall

be type 6063-T5 extruded aluminum with a 5/32" thickness minimum.

- The anti-slip surface

shall be chemically bonded onto the extrusion with an adhesive matrix

that is capable of 7.3 lbs per square inch peal strength - PSTC-1

- The anti-skid surface

shall be level with all surfaces of the extrusion.

- Treads shall be

noncombustible, as tested under Federal

- Test Method Standard

No. 501a. 11ethod6411, Mil-D-STD-16230.

- Treads shall meet

Mil-l -17951E. Motor Vehicle Safety Standard No.302. Treads are U.S.D.A.

approved.

- Specify acrylic

based construction adhesive for installation.

- Standard tread

design without drilled and countersunk holes. Addition of holes must

be specified (consult The Mat King).

- Unless otherwise

specified front and back anti-skid surface are standard flat black medium.

- Treads shall have

a coefficient of Friction per specification Mil-D-17951 E that is equal

to or greater than 1.24 Dry and 1.02 Wet.

- Anti-skid surface

shall consist of a uniform ”closed coat" of the specified

grade of mineral abrasive.

- The abrasive shall

be adhered to the substrate with a flexible polymeric binder in sufficient

thickness to achieve both optimum bond and grit exposure.

- The abrasive surface

has an underside with a uniform application of high tack permanent type

acrylic pressure-sensitive adhesive,

- The safety treads

shall be furnished straight and free from defects.

- All exposed aluminum

will have a satin finish.

- Color extends uniformly

throughout the abrasive surface.

|

|

![]()